Hi all,

A few months ago a few of you asked me if i could do a sbs on casting resin. It took a bit longer than planned

. But here it is

First of all, this is the way i learned it. Some of the moddelers who cast resin themselves may do it a bit different. And of course this is not the professional way

. I hope that with the help of the text and pictures you have enough info to start casting yourself. And if not, you can always ask me. For the pictures i'm using different sized moulds. Makes it's easyer to make a sbs.

Second, there wil proberly be some words of wich i don't now the english translation.....sorry for that.

But before we start, safety first!

Hope that didn't scare you off LOL

It's always important to have a mouthpiece as on the picture and some thin rubber gloves. Resin is't that good for your health. With these things and a good ventilated room it should cause a problem. As you can see on the pictures i didn't use rubber gloves.....i need to buy some new ones.

Part 1, making the part ready forthe mould.

I haven't made pictures for this so i'll say it in words. The part wich you are going to cast needs a casting block. Not to big, not to small. Try to make these on the side of the part wich you won't see after it's glued on the model. But do remember the casting block needs to be big enough to get the part out of the mould.

Part 2, making moulds.

For this you need rubber and hardener. You should be able to buy these at model shops.

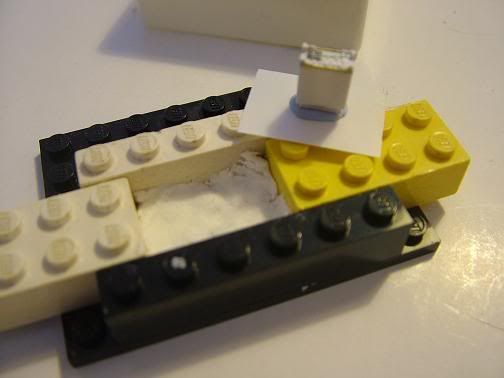

To make a mould i use lego blocks

and clay

I start with the lego blocks to make the size of the mould. The bottom is then filled up with clay. And on top of that comes the part sicked with bleu-teck on a piece of plastic. If you don't put the clay on the bottom the resin will go under the plastic card and if it works out bas the part you're planning to cast wil not be completely covered, I will show his later on.

Then some more lego blocks on top to make the final height of the mould, and take these of again.

When the mould is done you can use the legoblocks again to put the mould in when casting resin. This should reduce warpage.

In a metal cup i make a mix of the rubber and hardener. With a spoon i mix these two. When you're done making the moulds just leave the rest of the rubber in the cup. When it's dried you can pull it out. As you proberly make to much rubber for the mould(i always do) make sure you've got a few parts ready for making moulds. It's a waste to throw away that rubber. And if you've go a part wich is not completely covered with rubber....no problem, when it's dried you can put new rubber on top of it.

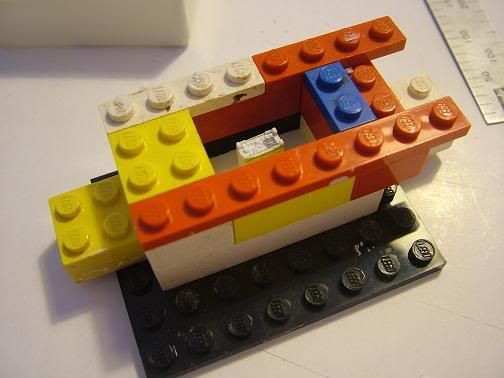

Now i'm using a wodden toothpick to put some rubber below the part. In this way i hope i won't get any airbubbles. As you can see i'using the radio wich i made for my YPR 765.

When the bottom is filled....

.......i put on the rest of te lego blocks......

.....and with the toothpick i put some rubber on the controlpanel of the radio to make sure there won't be any airbubbles.

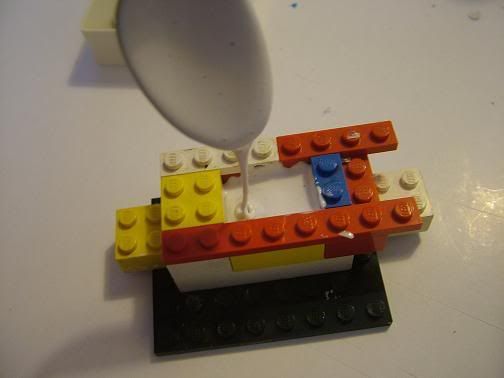

For the rest of the mould i'm dropping in the rubber with the spoon

And done.As you can see the rubber tops out of the lego blocks. But that's no problem.

The rubber will find it's way through the legoblocks as you can see. And that's why i put some clay on the bottom of the mould.

The excess rubber can easily be pealed of.

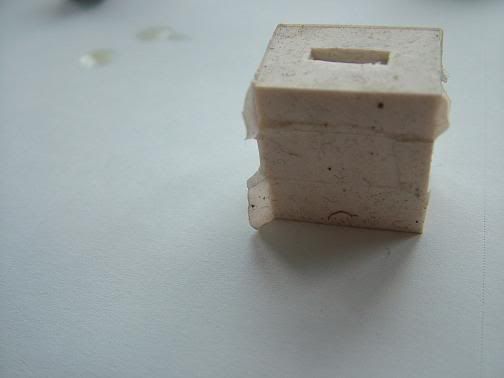

And you're mould is finished.

Now you can also make two part moulds. I can't tell you anything about this because i haven't tried this myself. Maby sometme later.